The State of Bulk Bag Handling

INDUSTRY OUTLOOK

Customers of bulk bag handling equipment and systems have experienced significant growth in the past year

and professionals at these companies must prepare for this trend to continue in the upcoming years.

Prepare for Growth

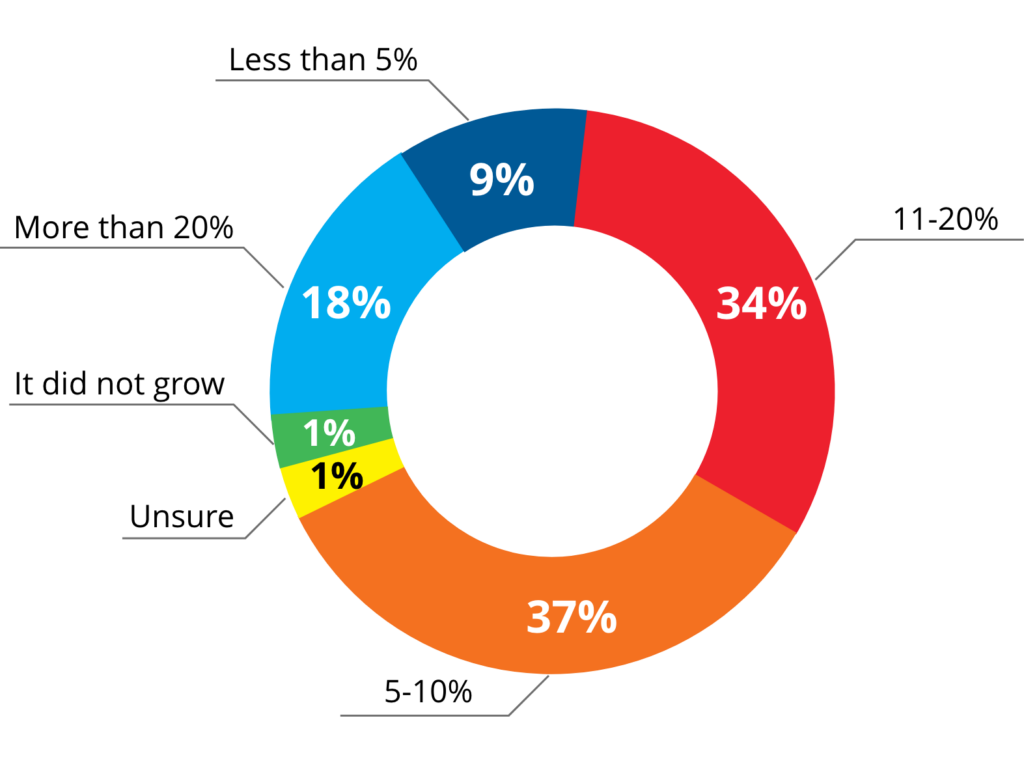

98% of industry professionals reported an upturn over the past year, with 52% experiencing growth rates exceeding 11%. This surge necessitates a strategic approach to equipment and facility upgrades, maintenance and overall efficiency of systems. The urgency to update equipment is further reinforced by the revelation that 77% of professionals plan to replace or upgrade their bulk bag handling systems within the next two years, with an even higher percentage in Mexico.

By approximately how much did your business GROW in the past year?

Supply chain issues were identified as the foremost challenge by industry professionals (50%), showcasing the critical importance of addressing logistical hurdles in the powder handling and dry solids processing industry. This is closely followed by concerns about product shortages (41%), indicating a direct correlation between supply chain challenges and the availability of essential products within the industry.

Industry Challenges by Region

US

| Supply chain issues: | 46% |

| Shifts in customer/consumer demands and preferences: | 46% |

| Economic disruption | 41% |

UK

| Supply chain issues: | 53% |

| Changing regulations and compliance: | 45% |

| Economic disruption/product shortages | 42% |

Canada

| Supply chain issues: | 58% |

| Product shortages: | 42% |

| Changing regulation and compliance | 37% |

Mexico

| Shifts in customer/consumer demands and preferences: | 52% |

| Supply chain issues: | 44% |

| Market saturation | 39% |

What do you consider to be the TOP CHALLENGES facing the

powders and dry solids industry?

| Supply chain issues |

50%

|

| Product shortages | 41%

|

| Shifts in customer/consumer demand and preferences | 38% |

| Changing regulations and compliance | 38% |

| Economic disruption | 36% |

| Traceability and transparency | 31% |

| Market saturation | 30% |

What are the TOP BULK BAG HANDLING CHALLENGES

professionals have with their equipment?

| Material contamination |

39%

|

| Maintaining consistent flow from bulk bags |

36%

|

| Inaccurate weighing |

33%

|

| Filled bulk bag stability |

29%

|

| Material segregation |

26%

|

| Bulk bag discharging rate is too low |

26%

|

| Bulk bag filling rate is too low |

25%

|

Need help overcoming some of the top

bulk bag handling challenges?

Cone Table Elite (CTE) Bulk Bag Filler – The Leader in Fast, Accurate Bagging

Spiroflow’s cone table densifier removes air from light materials with a hanging bag design that allows for quick and efficient bag filling. Custom features include:

Powered Height Adjustment: This option lets the operator quickly adjust the height between filling cycles to accommodate bulk bags of differing sizes.

Densification System: During filling, vibrators improve material densification in the bulk bag. This increases productivity and ensures that filled bags are safe for further handling, storage or transportation.

Roller Conveyors: Enable filled bags to be removed from the filler and staged on roller conveyors where they can be picked up by a forklift for increased productivity.

Reasons for Updating Your System

What reasons did industry professionals cite for wanting to update their bulk handling equipment or systems?

Out of the 7 reasons supplied, productivity improvements, enhanced safety features, improved energy efficiency and reduced downtime were the biggest.

The Purchasing Process

The demand for new bulk bag handling equipment is strong considering 66% of companies have shopped for or purchased new equipment in the past 12 months. In addition, 77% of companies report planning to update or replace bulk bag handling equipment in the next two years.

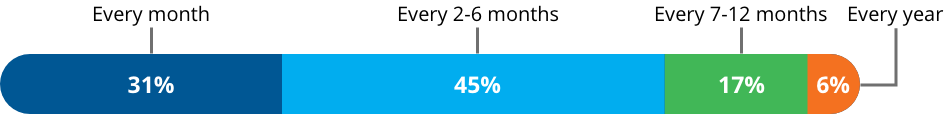

Evaluating Your System Is Key The purchasing process begins with companies evaluating their existing bulk handling equipment and system(s), a task undertaken with a high level of frequency. Specifically, 31% of companies evaluate equipment every month and another 45% indicated performing evaluations every 2-6 months.

How frequently do you EVALUATE the performance of your bulk bag handling equipment and system(s)?

Correlation between satisfaction and evaluation: Those who are extremely satisfied with their systems also evaluate them more frequently (44% every month), suggesting a proactive approach to evaluation may be linked with higher satisfaction levels.

Shopping for New Bulk Bag Handling Equipment

| Equipment reliability and durability |

46%

|

| Purchase price |

46%

|

| Hygiene and contamination control |

39%

|

| Weighing accuracy |

39%

|

| Filled bag stability |

38%

|

| Dust control |

36%

|

| Throughput capacity |

34%

|

Need some help preparing for the

purchasing process?

Download Our Bulk Bag System Shopping Checklist

What to Test Before You Buy

An overwhelming 97% of respondents concur that testing a new system before purchase is essential. But what parts of your bulk bag system should you be testing? Here’s a breakdown of what the survey’s respondents said is most important:

| Weighing accuracy |

52%

|

| Cleanability of system |

46%

|

| Dust emission testing |

43%

|

| Flow rate from bulk bags |

40%

|

| Densification/compaction |

35%

|

| Looking for the test to reveal unknown issues |

35%

|

| Ergonomics |

34%

|

| Throughput |

30%

|

| Using a shorter bulk bag to contain the same weight of material |

29%

|

| Filling more product in the same size bulk bag |

28%

|

Want more details on the things you

should test before buying?

Read Our Testing Blog