Facing aero mechanical conveyor problems can disrupt the smooth flow of materials, affecting overall productivity. Ensuring your conveying system operates efficiently is key to maintaining a seamless material handling process. Understanding and solving common problems can keep your materials moving smoothly. This overview explores practical solutions and maintenance tips to enhance the reliability and performance of your aero mechanical conveyor.

Spiroflow Can Help With Your Aero Mechanical Conveyor Problems

What are the problems with aero mechanical conveyors? If you work in the processing industry, it’s completely understandable if this question is on your mind. There’s nothing inherently flawed with an aero mechanical conveyor (AMC). However, issues can arise when these conveying technologies are used or set up incorrectly. Don’t worry! We’ll talk about how you can avoid headaches while using an aero mechanical conveyor in your operations.

What do we know? Here at Spiroflow, we’ve been in the dry bulk material handling industry for nearly five decades. It’s been our goal since our launch to provide quality custom-designed conveyor solutions to our customers and to make sure those conveyors work to the best of their capabilities. That starts with us understanding your needs.

What Is an Aero Mechanical Conveyor?

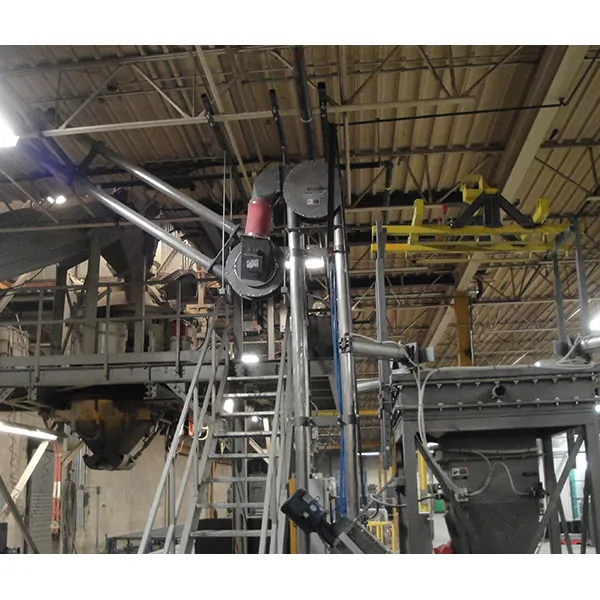

Before we go any further, let’s explain how we define an aero mechanical conveyor and what it’s used for. An AMC moves material from point A to point B at a high rate. It utilizes a cable and disc assembly, and it’s dust-free. The discs create an airstream that carries the material. Each pocket is made up of about 80% air and 20% material. This keeps the material from being dragged along the tube. This type of conveyor provides a total batch transfer.

What Are Its Speeds and Capacities?

The speed and capacity rates of an aero mechanical conveyor can vary depending on the conveyor’s size. For example, at Spiroflow, we design and manufacture AMCs in 3″ (75mm), 4″(100mm), and 5″ (125mm) diameters. Speeds and capacities can vary depending on the material that needs to be conveyed. AMCs don’t have variable conveying rates.

How to Avoid Aero Mechanical Conveyor Problems?

Preventing issues with aero mechanical conveyors starts with proper usage. Misuse leads to the majority of operational problems encountered with AMCs. Let’s talk about the key practices to avoid aero mechanical conveyor problems, ensuring your industrial conveyor systems operate at their best. By understanding and applying correct operational techniques, you can maintain the efficiency and longevity of your AMC system.

Keep the Proper Tension

The most common thing customers do wrong with AMCs is operate them without proper tension on the cable. The cable is easily damaged if the tension is too tight or too loose. This is why an auto-tensioning system will make your life much easier – trust us on this one! Spiroflow has developed a patented Dynamic Automatic Rope Tensioning system – or DART – precisely for this purpose.

The rope (or cable) tends to stretch over time. The DART system uses an air cylinder at one of the housings to maintain constant pressure. This keeps the tension on the sprocket and keeps the rope or cable on track. Overall, the DART saves you from manually having to check and adjust the tension and prevents equipment failure, which keeps your process moving.

Monitor the Sprockets

Problems can also be avoided if the operators regularly inspect the AMC’s sprockets. Placing a new cable on a worn sprocket defeats the purpose of a new cable. A worn sprocket will destroy a new cable very quickly.

Pay Attention to the Product

Although aero mechanical conveyors can run empty, running them while empty reduces the number of hours the system or its components will last. It’s best to allow the conveyor to shut down and sit idle in between times when material is transferred.

Overfeeding can be a problem as well. Trying to max out the capacity of the AMC can put too much strain on the components. This also goes back to correctly sizing your conveyor for your application. An experienced supplier can ensure the recommended system is correctly sized to meet your required rate without overfeeding. We strongly recommend material testing regardless of the product you plan to run. Utilizing a test lab early on will prevent problems in the future.

We Offer Top-Rated Conveyor Solutions for Various Industries – Reach Out and Improve Your Conveying Processes

Spiroflow is about more than just AMCs – we offer various conveyor technologies for a wide range of industries. Be sure to check out our full line of products and find industrial conveyor systems that best fit your processing needs. We also do control systems integration – our automation solutions are unparalleled, and our conveyor manufacturers are the best experts in their field. Contact us today, and let’s work on improving your conveying process together.

FAQ

What Common Problems Occur With Aero Mechanical Conveyors?

Aero mechanical conveyors (AMCs) typically face issues when not used or set up correctly. Improper tension on the cable, incorrect sizing for the application, and overfeeding are common pitfalls that can lead to operational inefficiencies and increased wear and tear.

How Does Proper Usage Prevent AMC Problems?

By adhering to correct operational practices, such as maintaining the correct tension on the cable and avoiding overfeeding, users can significantly reduce the risk of operational problems. Spiroflow’s patented DART system is designed to automatically adjust cable tension, ensuring the AMC’s optimal performance and longevity.

What Is the Importance of Tension in AMC Operations?

Correct tension is crucial for AMC operations. Too much or too little tension can damage the cable, leading to failures. The Dynamic Automatic Rope Tensioning (DART) system developed by Spiroflow helps maintain constant tension, preventing common issues and extending the equipment’s life.

Can Running an AMC Empty Cause Issues?

Yes, running an AMC empty can shorten the lifespan of the conveyor and its components. It’s advisable to shut down the conveyor and let it sit idle between material transfers to preserve its longevity and efficiency.

How Can Overfeeding Affect an AMC?

Overfeeding an AMC can strain the system’s components, potentially leading to premature wear or failure. It’s essential to size the conveyor correctly for your application and consider material testing to ensure the system can handle the intended capacity without issues.