When considering conveying carbon black and the best conveyors for that particular job, it’s important to understand the challenges. We should get in-depth about both the unique properties of carbon black as a material and the specific requirements for its effective transportation.

What Is Carbon Black And What Is It Used For?

Carbon black is made by the incomplete combustion of petroleum and is used as a pigment or coloring agent in ink, paint, and many other substances. Due to its ability to increase resistance to wear and abrasion, carbon black is also commonly used as a reinforcing agent for tires, protective coatings, and resistors for electric circuits.

Carbon black is considered a Group 2B carcinogen, “possibly carcinogenic to humans.” Therefore, choosing the right conveyor that will effectively move the material whilst minimizing any possibility of potentially harmful dust emissions is essential. As with all potentially hazardous materials, wearing appropriate PPE when working in the presence of carbon black is essential for the protection of operators, even with suitable dust control solutions in place.

Carbon Black Vs. Activated Carbon

Carbon black can come in a variety of forms, each with several different names, and it is often confused with the activated carbon or activated charcoal family of products. While both carbon black and activated carbon are used as absorbing agents, and both have a high surface area compared to their volume (which is what makes them both good absorbing agents,) their material properties and, thus, material handling difficulty differ. So, first and foremost, we will try to clarify the key differences between the key product types.

| Carbon black | Activated carbon (a.k.a. activated charcoal) | |

| Source | Formed from the incomplete combustion of petroleum | Derived from charcoal |

| Applications | Reinforcing agent (ie. tires, protective coatings, resistors for electric circuit) | Filtration & purification (ie. water, air, gasses) |

| Surface area | High surface-area-to-volume ratio (but lower than that of activated carbon) | Very high surface-area-to-volume ratio |

| Particle size | Fine in powdered form (though it can be pelletized to increase particle size) | Large, granular |

Powdered Carbon Black – Challenges in Conveyance

Powdered carbon black is a very fine fluid-like powder with an extremely low bulk density (typically <15 lbs/cu. ft.). These fine powders, often referred to as “fluff,” can be challenging to handle and convey. Care must be taken to avoid the powder caking and clogging the conveyor, resulting in downtime and increased safety hazards during maintenance and cleaning. Additionally, finely powdered carbon black can easily become airborne, making controlling dust emissions of utmost importance.

Pelletized Carbon Black – Handling and Considerations

Pelletized carbon black (often referred to as “prills” or “beaded” carbon black) are larger particles and have typical bulk densities in the 15-20 lb/cu.ft. range. The larger particle size and higher bulk density make this form of carbon black easier to convey. While pellets have better flow characteristics and can reduce potentially harmful dust emissions, they can still be easily crushed during transportation or prone to breakage when being conveyed, which can eliminate many of the benefits of their use. Thus, careful consideration of conveyor type needs to be made to avoid degradation and the loss of some of the beneficial qualities of this pelletized form.

Activated Carbon – Distinct Characteristics and Conveyance

Activated carbon (also known as activated charcoal), often confused with carbon black, has significantly different material properties and is typically much easier to handle. With larger particle sizes and a more granular makeup, activated carbons normally have bulk densities above 20 lbs/cu.ft and exhibit better flow characteristics compared to their petroleum-derived cousins. As a result, these products can often be successfully conveyed in a variety of conveyor belt systems, such as flexible screw conveyor or tubular drags.

Carbon Black Conveyor Considerations

When designing a belt conveyor system for true carbon black, the first thing to consider is the format of the material that will be conveyed (powdered vs. pelletized).

Conveying Powdered Carbon Black

If you must convey carbon black in its powdered form (“fluff”), then a fully enclosed conveyor design that can effectively move this very low-density, fine powder with maximum dust mitigation will be the most important requirement. Pneumatic conveying, or the use of specialist “diaphragm” pumps, can be good options for long distances and high rates but require highly efficient air/material separators. Additionally, the resulting conveyor belt systems can use large amounts of energy and require regular and expensive maintenance.

Conveying Pelletized Carbon Black

If your process will allow it, using carbon black in pelletized form (prills or beads) is strongly recommended. Pellets are easier to convey and bring fewer safety risks associated with fugitive dust. Selecting a gentle form of conveyor will be key to preventing the friable pellets from rubbing against one another and creating carbon black dust to maintain the beneficial characteristics of the pelletized product. Dense phase pneumatic conveying can be a good option, but once again, it can have very high energy requirements.

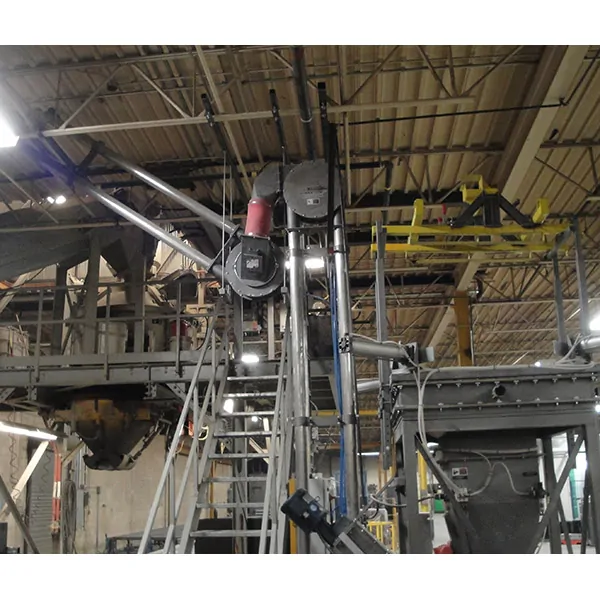

Aeromechanical Industrial Conveyor Systems – An Efficient Alternative

An extremely efficient, clean, and reliable alternative is the aero mechanical conveyor. This type of system offers an effective solution to the challenges posed by both powdered and pelletized forms of carbon black.

Aero Mechanical Conveyor

An aeromechanical conveyor is a great choice for conveying challenging materials, like pelletized carbon black, because of its unique and gentle conveying method. The cable assembly travels through the conveyor tubes at significantly lower speeds than dilute phase pneumatic conveying systems but is fast enough to create pockets of air, which entrain the carbon black pellets in a cushion of air. This airstream with suspended particles results in significantly fewer shear forces than would be created in a screw or drag conveyor and minimizes breakage of the pellets and prevents caking and packing inside the tube.

The aeromechanical conveyor is also a fully enclosed dust-tight conveyor that does not require an additional dust collection system for containment since no air is being added to the conveyor to provide the motive force for the material.

When Conveying Carbon Black, the Best Conveyors Are Found at Spiroflow

If you’re facing challenges in moving carbon black, whether in powdered or pelletized form, or if you’re experiencing difficulties with your current carbon black conveying system, Spiroflow is here to help. Our team of experts specializes in handling various forms of carbon black and can offer tailored solutions to meet your specific needs. Don’t hesitate to reach out – contact Spiroflow today, and one of our knowledgeable representatives will promptly respond to engage in a detailed discussion about your process and how we can assist in optimizing your carbon black handling and conveyance.