Weighing and Batching Solutions

Precise weighing and batching solutions are crucial for maintaining product quality and operational efficiency. These systems are essential in minimizing material waste and maximizing resource utilization. In turn, it directly impacts a company’s bottom line by optimizing the cost-effectiveness of production processes.

Loss-in-weight Chemical Dosing Systems

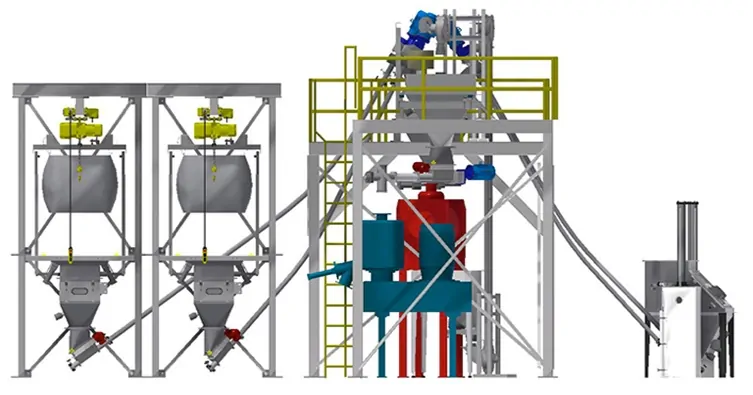

Engineers at Spiroflow crafted a specialized loss-in-weight chemical dosing system, tailored for a prominent battery producer catering to the military and healthcare sectors. This innovative system combines a unique blend of carbon black, graphite, and two varieties of EMD. It employs two bulk bag dischargers that feed EMD into a hopper.

Additionally, carbon black and graphite are conveyed to the same hopper through two bag dump stations equipped with glove boxes, bag compactors, and versatile flexible screw conveyors. Subsequently, the hopper channels these materials into a blender for thorough mixing.

Post-mixing, the blend is transferred using an aero mechanical conveyor to another mixing station, ensuring the precision of the loss-in-weight batch size. Finally, a horizontal flexible screw conveyor from the extensive range of conveyor solutions efficiently transports the dry mix to an additional mixer for the integration of liquid components. This process exemplifies the cutting-edge conveyor technologies and conveyor belt solutions provided by the leading conveyor systems manufacturers – Spiroflow. It showcases our commitment to delivering comprehensive industrial conveyor systems.

Gain-in-weight Bulk Bag Filling Systems

Three distinct bulk bag fillers were essential to create a custom-made PVC flour dust process tailored to a major carpet producer. Positioned above, a dispensing unit equipped with a rotary airlock, diverter valve, and slide gate efficiently channels PVC flour dust into a twin, gain-in-weight bulk bag filling system.

This system, carefully engineered for superior bagging rates and enhanced operator efficiency, allows the simultaneous filling of one bulk bag while facilitating the replacement of another. This seamless operation is a testament to the innovative conveyor belt systems and solutions provided by specialized conveyor manufacturers such as Spiroflow.

Additionally, a third bulk bag filler stands ready to accommodate PVC flour dust amassed through a comprehensive plant-wide dust collection system. This filler is consistently replenished by a flexible screw conveyor, an integral part of the belt conveyor system, drawing from a designated external source. This setup not only epitomizes the efficiency of modern conveyor belt systems but also highlights the precision engineering of leading belt conveyor manufacturers in meeting industrial needs.

Weighing and Batching Solutions For Operational Efficiency

The tailor-made Loss-in-Weight Chemical Dosing System and the custom-made PVC flour dust Bulk Bag Filling Systems stand as exemplary representations of advanced engineering and precise manufacturing. By integrating sophisticated conveyor belts and other equipment, we cater to specific industrial needs, ensuring efficiency, accuracy, and productivity.

As a result, each part of our systematic solution, from the conveyor belt system to filling and unloading, meets the rigorous requirements of specialized applications. These systems are a testament to the commitment to excellence in the field of industrial conveyor systems. They demonstrate that precise engineering and thoughtful design can significantly enhance operational effectiveness and product quality in diverse industrial landscapes.

Need Assistance? Contact us today, we’ll return a response ASAP